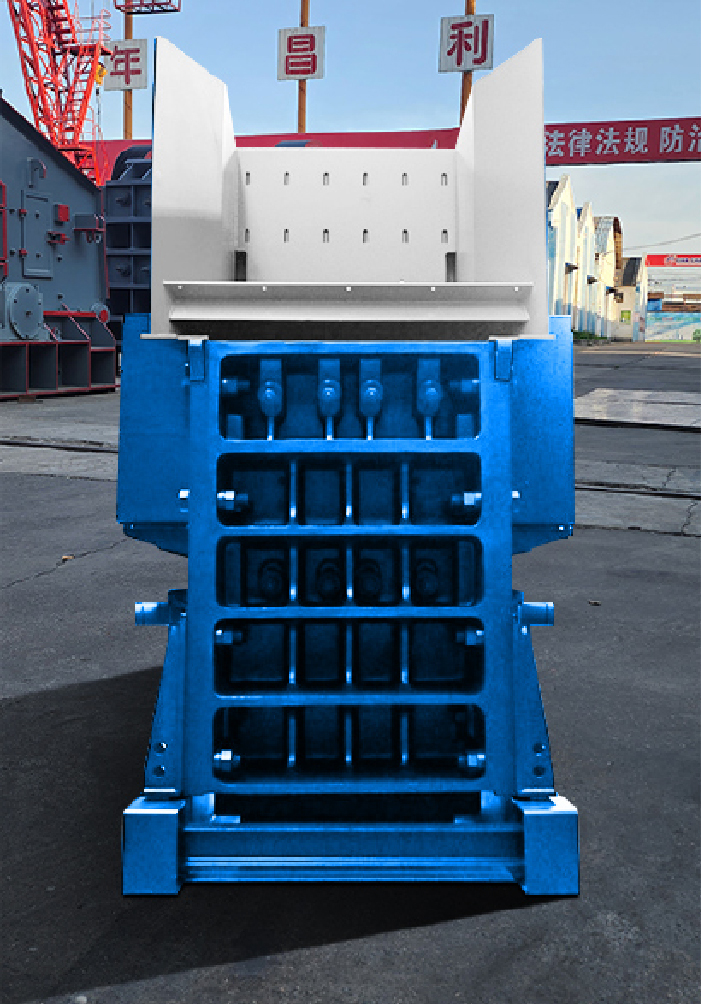

High Crushing Ratio / High Productivity / Sturdy and Durable

CJ Series Euro-style Jaw Crusher

Capacity: 50~2700 t/h

Equipment Introduction

The CJ series Euro-style jaw crusher, developed and produced by Talus Equipment Manufacturing, adopts advanced technology and has become a popular jaw crusher worldwide. It represents leading crushing technology and manufacturing level for coarse crushing of hard and highly abrasive materials. The CJ series jaw crushers feature innovative modular, non-welded frame structures, enhancing the equipment's anti-fatigue ability, reliability, and simplifying various installation methods. Compared to traditional jaw crushers, it utilizes high-strength materials in the manufacturing process, resulting in high structural strength, equipment reliability, larger crushing ratio, higher productivity, and lower overall cost.

Large Crushing Ratio

High Productivity

Security and Stability

High Comprehensive Benefit

Easy Operation and Maintenance

Good Granularity of Final Product

Product Performance

Sturdy Structure

Sturdy Structure

The machine frame comes in two types: welded mode for small and medium sizes and assembled mode for large sizes.

Durable Heavy-duty Movable Jaw Assembly

Durable Heavy-duty Movable Jaw Assembly

The heavy-duty movable jaw assembly adopts forged heavy eccentric shafts, high-quality heavy-duty rolling bearings, and a movable jaw plate optimized by finite element analysis software. This ensures high impact resistance and stability of the movable jaw assembly. The labyrinth seal and centralized lubrication system prevent contamination of the bearing grease, making lubrication more convenient and increasing the running time and stability.

Integrated Bearing Pedestal

Integrated Bearing Pedestal

The integral cast steel bearing pedestal structure ensures compatibility with the frame, avoiding unnecessary radial loads on the bearing during the fastening of the combined bearing pedestal. This ensures smoother bearing operation.

Integrated Motor Installation

Integrated Motor Installation

The integrated motor bracket and crusher frame installation not only save installation space and reduce the length of triangular belt but also enable the adjustment of the triangle belt tension due to the synchronous movement of the motor, motor bracket and motor pedestal. This results in a longer service life of the triangle belt.

Optimized Cavity Design

Optimized Cavity Design

The symmetrical "V" shaped cavity design, steep bracket angle and large stroke of toggle plate, and reasonable rotational speed allow for a larger feeding size, higher output, more uniform granularity, and less wear of the jaw plate.

Design of Movable Jaw Plate

Design of Movable Jaw Plate

A heavy duty protective plate is installed on the movable jaw to avoid material impact and effectively protects the movable jaw body and internal bearing from damage.

Convenient and Quick Granularity Adjustment

Convenient and Quick Granularity Adjustment

The JC jaw crusher adopts a mechanical or hydraulic discharge opening adjusting device, and its double block adjusting mode is simpler, safer and faster than the corresponding gasket adjusting operation, saving downtime.

Vibration Damping Installation Design

Vibration Damping Installation Design

The crusher is fixed with a special rubber vibration damping device that effectively absorbs the vibration peaks of the equipment. It allows the crusher to displace in vertical and horizontal directions, reducing the impact on the foundation.

Operation Principle

The electric motor drives the belt and pulley, which in return drives the eccentric shaft to swing the movable jaw up and down. When the movable jaw raises, the angle between the toggle plate and the movable jaw increases, then pushes movable jaw plate closer to fixed jaw plate. This crushes or chops the material. When the moving jaw descends, the angle between the toggle plate and the moving jaw decreases, moving jaw plate leaves fixed jaw plate away under the action of spring and tension rod. Meanwhile chopped material is discharged from hopper outlet of crushing cavity.

Technical Parameter

| Model |

Max. feeding size (mm) |

Capacity (t/h) |

| CJ96 |

480 |

105~390 |

| CJ106 |

560 |

150~500 |

| CJ120 |

700 |

175~610 |

| CJ125 |

760 |

270~831 |

| CJ150 |

960 |

340~880 |

| CJ160 |

960 |

430~1145 |

| CJ200 |

1200 |

630~1435 |

| CJ1511 |

850 |

425~1195 |

| CJ1513 |

1040 |

530~1280 |

Remark: The output may vary depending on the nature or grain size of the feeding material.

Product Show

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

Sturdy Structure

Sturdy Structure

Durable Heavy-duty Movable Jaw Assembly

Durable Heavy-duty Movable Jaw Assembly

Integrated Bearing Pedestal

Integrated Bearing Pedestal

Integrated Motor Installation

Integrated Motor Installation

Optimized Cavity Design

Optimized Cavity Design

Design of Movable Jaw Plate

Design of Movable Jaw Plate

Convenient and Quick Granularity Adjustment

Convenient and Quick Granularity Adjustment

Vibration Damping Installation Design

Vibration Damping Installation Design