High Crushing Ratio / Wear Resistance / Good Granularity of Finished Products / Operate Smoothly

CLV Vertical Shaft Impact Sand Making Machine

Capacity: 8-160 t/h

Equipment Introduction

The CLV vertical shaft impact sand maker adopts a series of new technical achievements such as four-port impeller structure, patented bearing cylinder design, high efficiency and low cost crushing cavity and large throughput frame. As well as optimized design of the overall function, ensuring that the crushing efficiency, operating cost, and operation and maintenance performance of the equipment have reached the advanced level at home and abroad.

High sand making efficiency

Long service life

Safety and stability

Low energy consumption

High level of automation

Good granularity of finished products

Product Technology

Our team of experienced experts, who have worked in the crushing and screening division of a renowned international crusher manufacturer for 5 years, possess extensive knowledge in manufacturing, quality management and after-sales service. They have mastered the complete technical system and quality management of crusher parts manufacturing, production assembly, installation and commissioning, and after-sales troubleshooting.

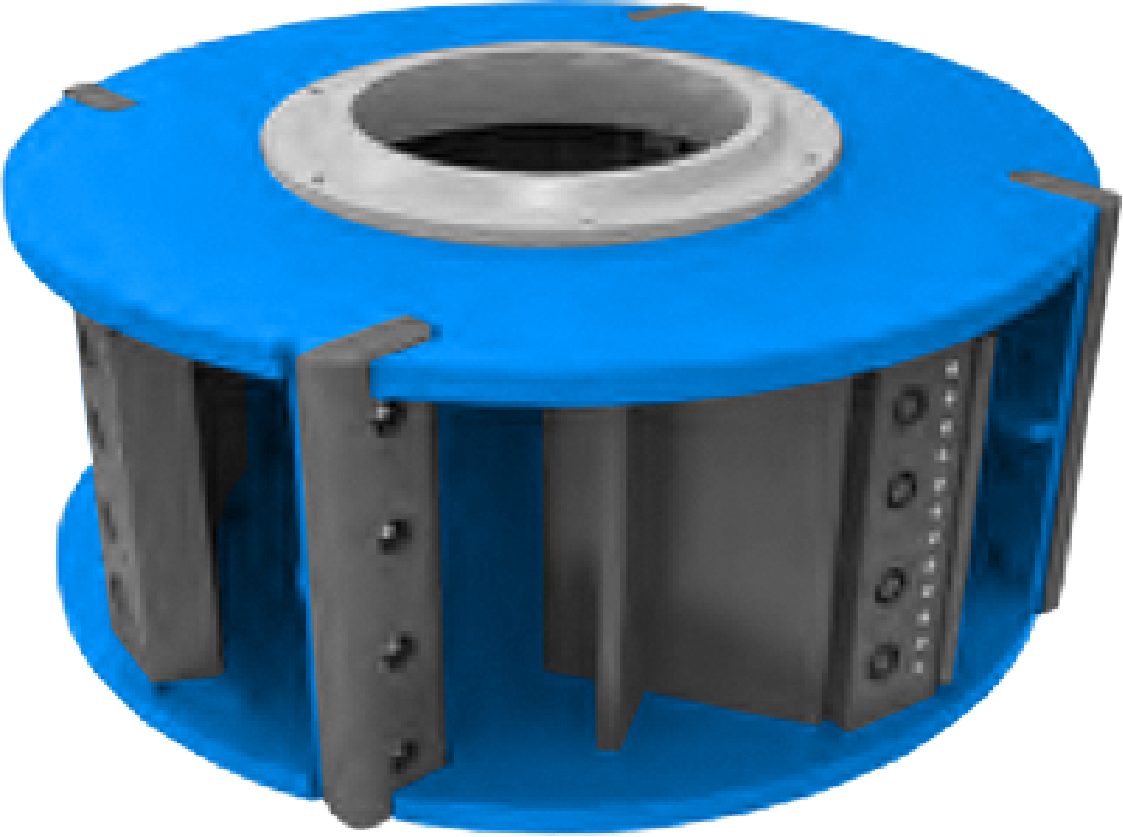

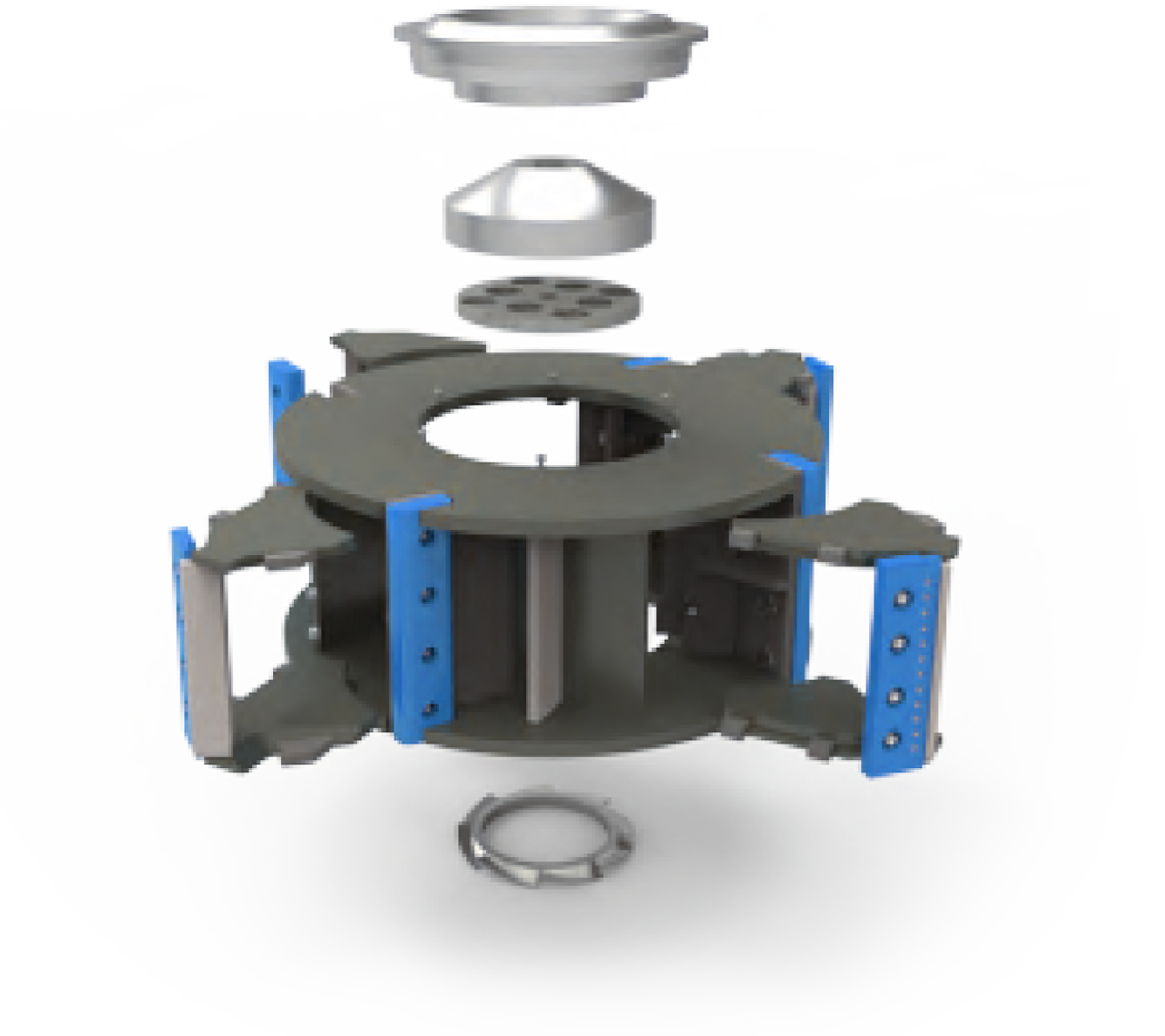

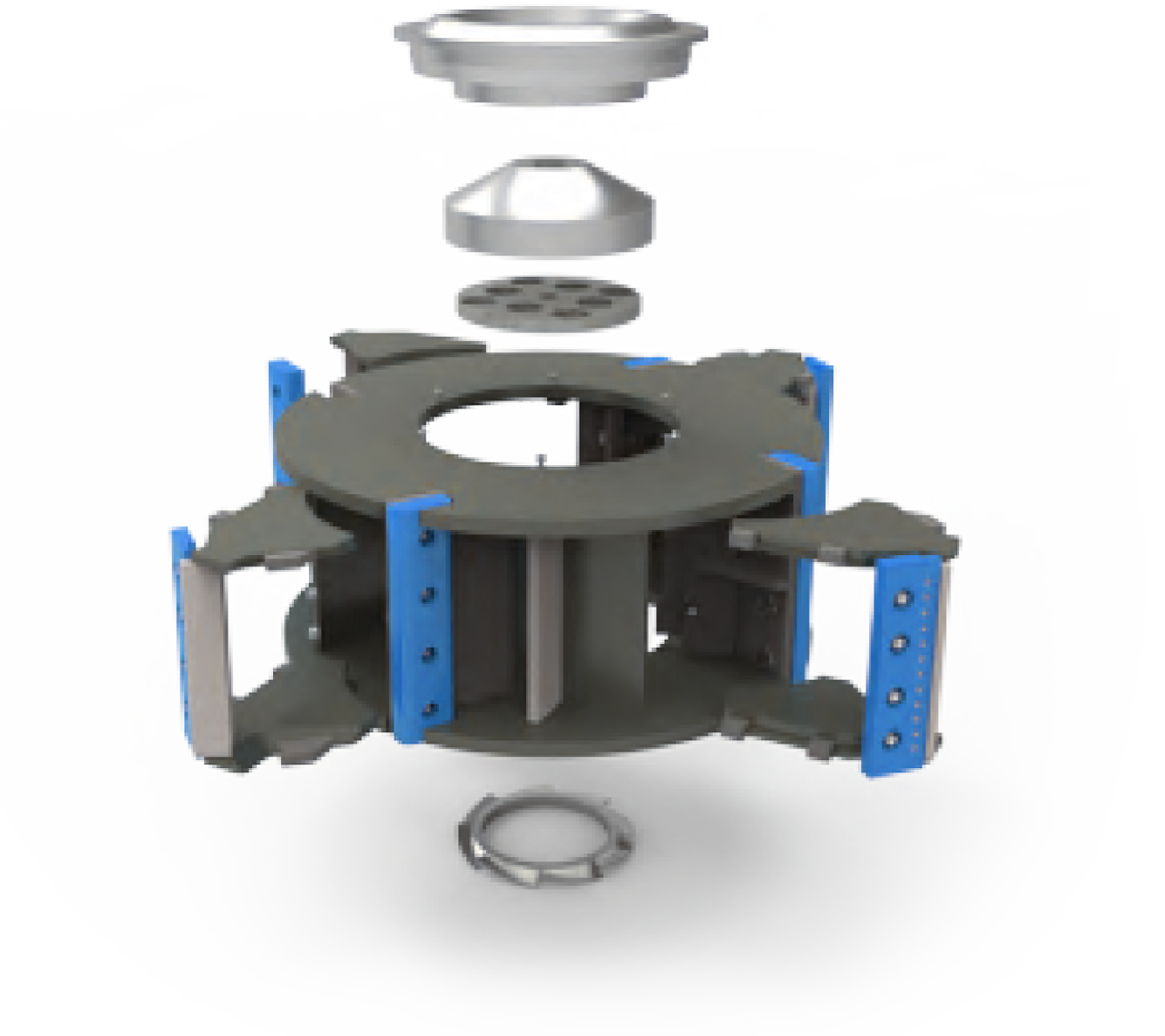

High Efficiency Four-port Deep-cavity Impeller

To enhance sand making efficiency, the CLV series vertical shaft impact sand maker features a new design with a four-port deep-cavity impeller. This design optimizes the material projection angle and speed, resulting in a large throughput, and a crushing efficiency increase of over 20% compared to a three-port impeller with the same material.

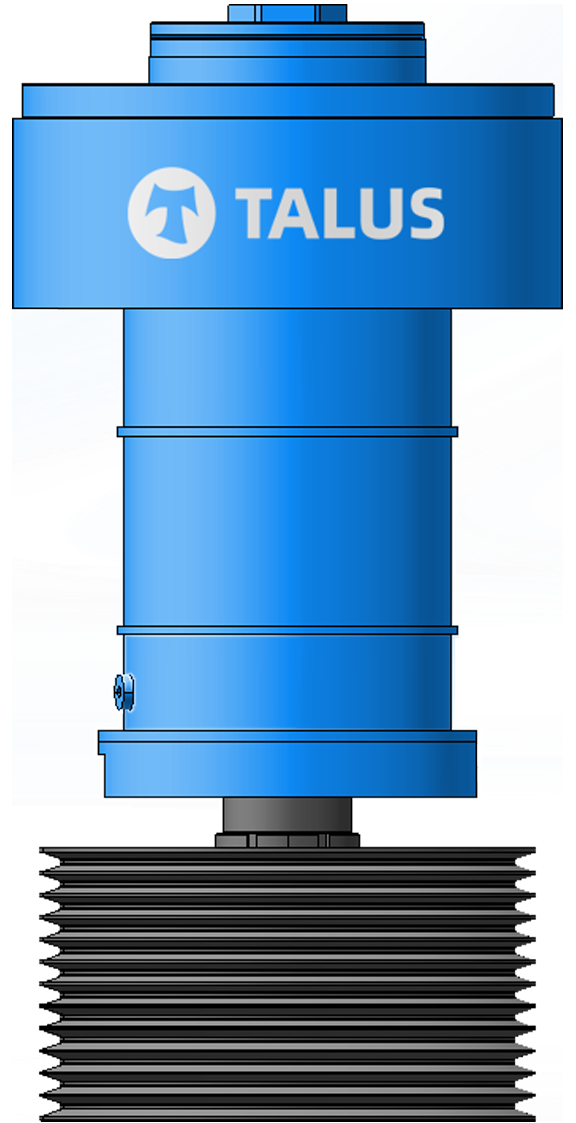

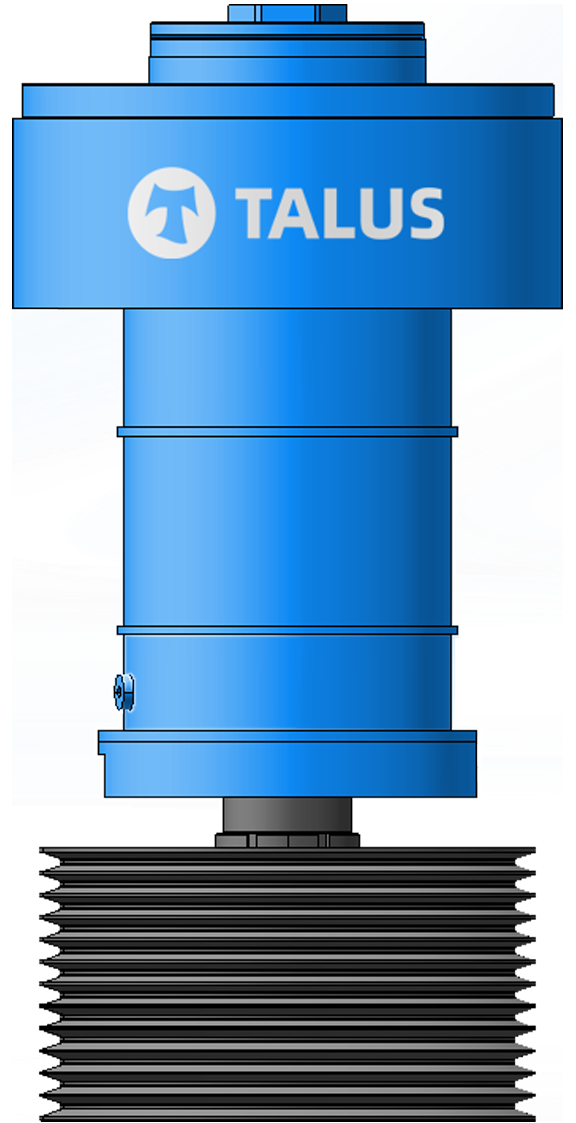

Innovative Bearing Cylinder Design

The CLV series vertical shaft impact sand maker introduces a new structure design for the bearing cylinder. The design features a special dust-proof and sealing structure, which obtains a number of national patents, supporting imported bearings. It further ensures the reliability of rotation.

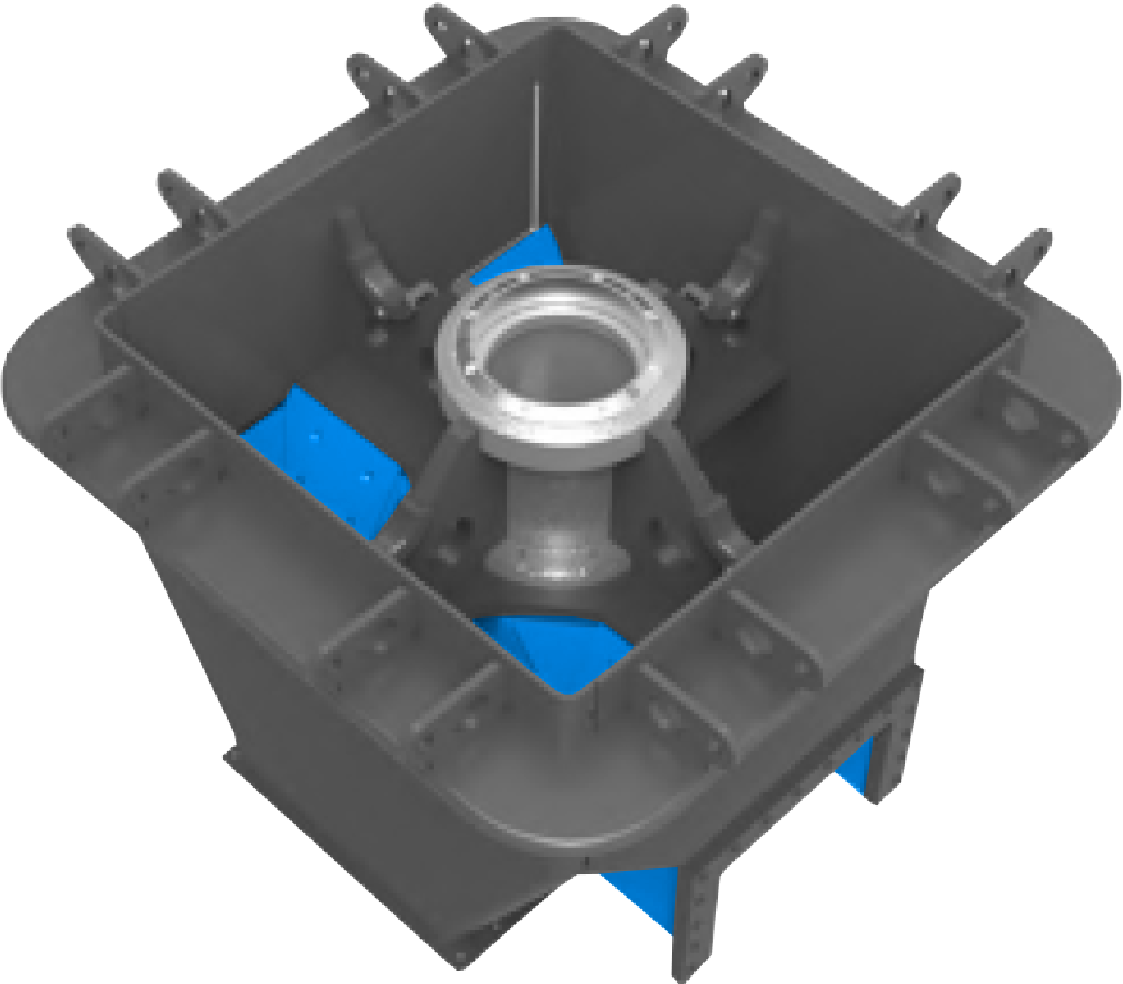

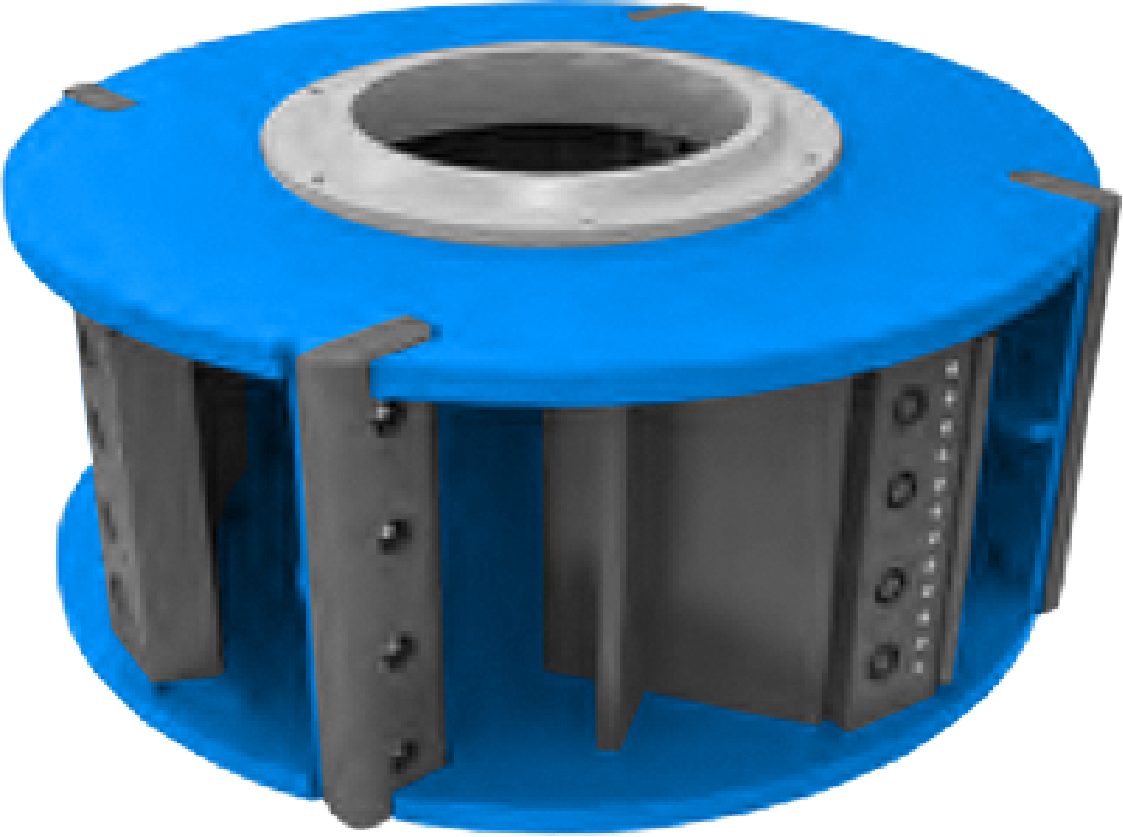

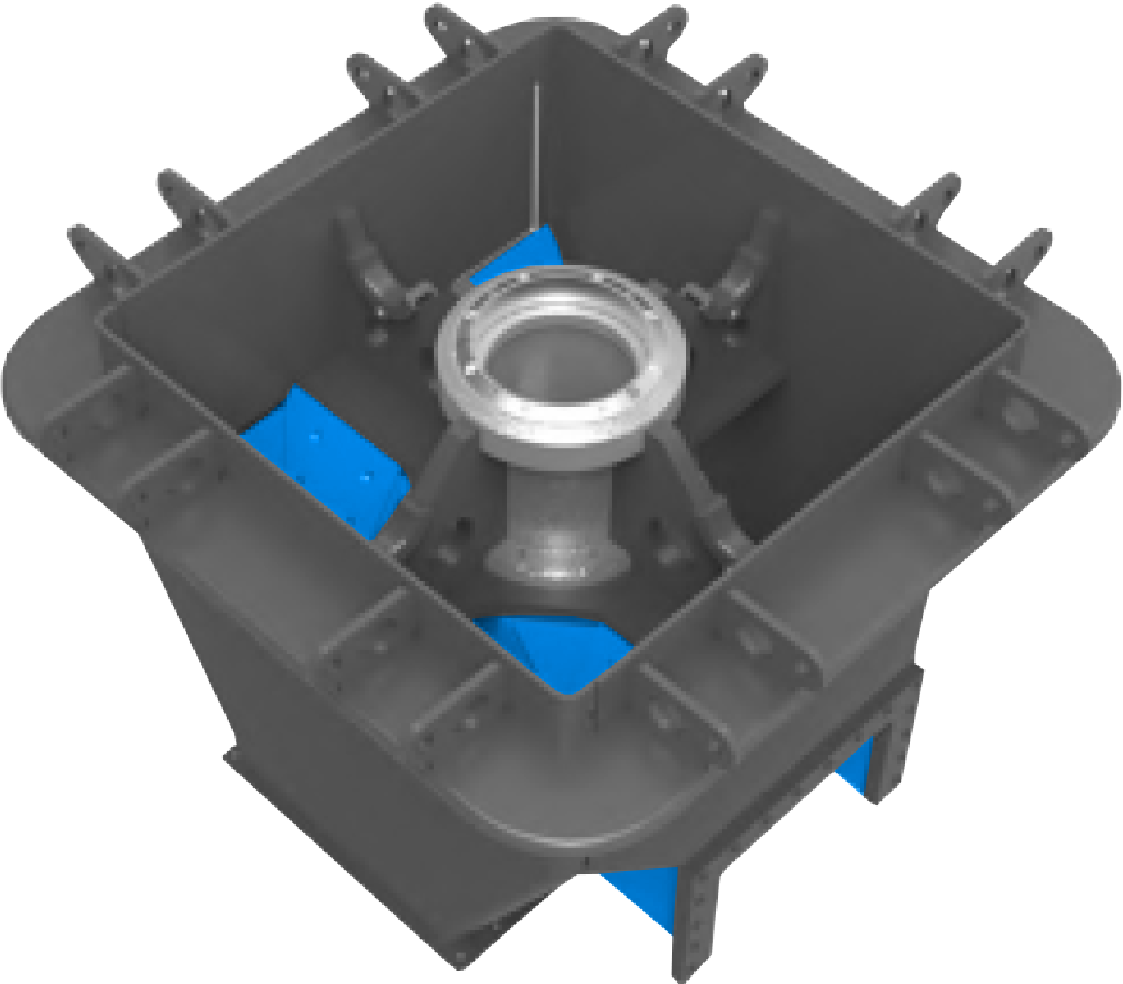

Large Throughput of the Main Body

The main body of vertical shaft impact sand maker adopts a simple design of large throughput, which effectively prevents the materials with excessive water content from clogging in the lower part of the body and improves the crushing efficiency of the whole machine.

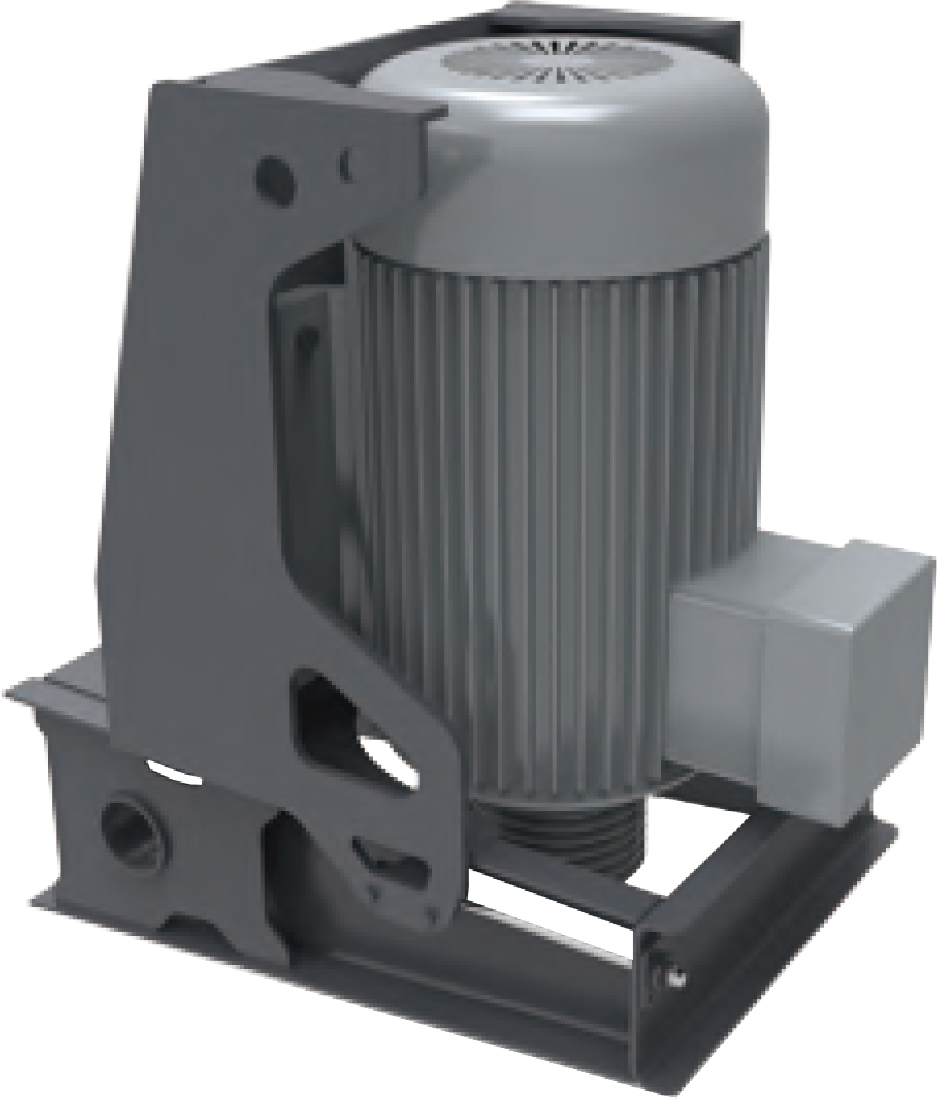

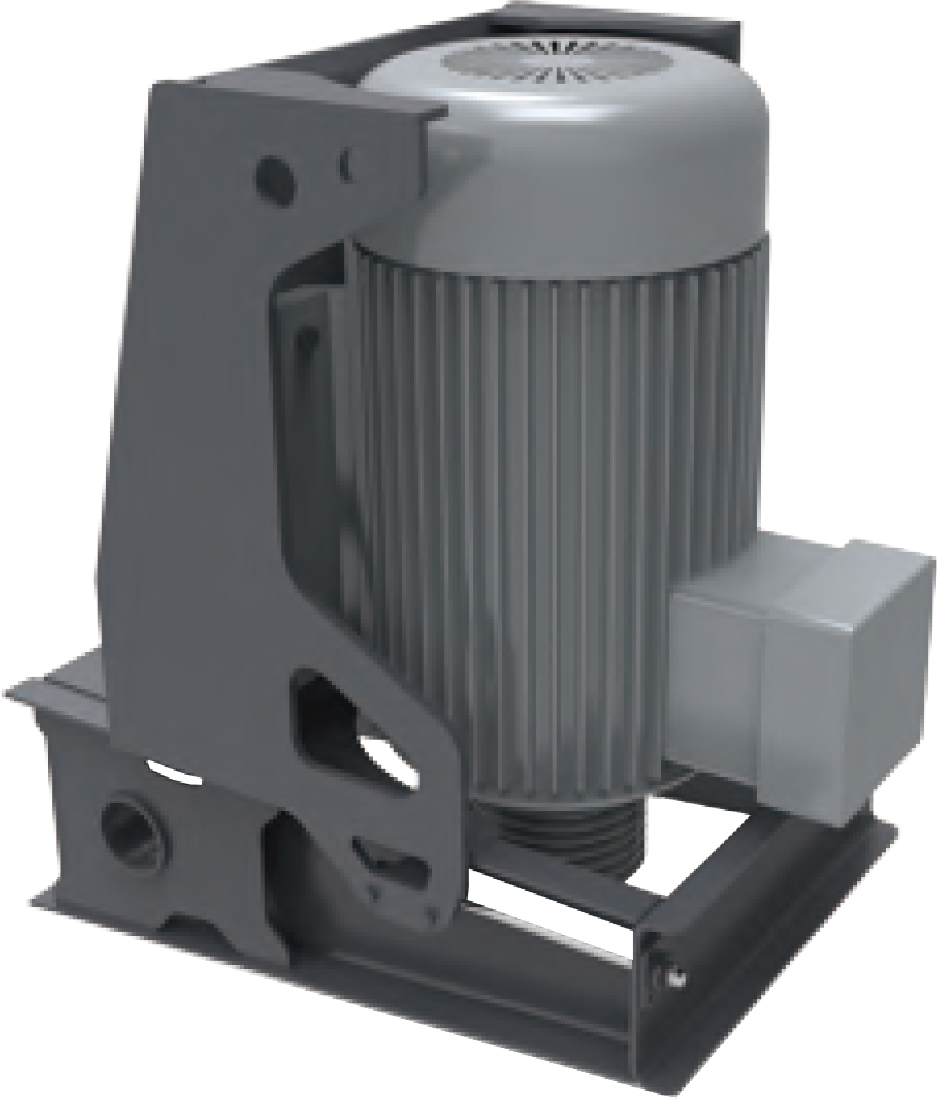

Smooth Dual-motor Drive

The CLV series vertical shaft impact sand maker operates at a high rotation speed and utilizes a dual-motor drive, resulting in higher transmission efficiency, uniform radial force on the spindle, and smoother operation. The optimized fixed structure of the motor bracket ensures reliable motor fixation and facilitates motor installation and adjustment.

Enhanced Durability and Cost-effectiveness

The impeller, which is the core component of the equipment, undergoes optimization in structure and process, and utilizes high-quality wear-resistant materials. This significantly improves the service life of the wearing parts, reducing the cost of maintenance. When processing super-hard materials, the "rock on rock" mode of operation is recommended to minimize wear and lower the cost of use.

Easy Maintenance with Lifting Device

CLV series vertical shaft impact sand maker is equipped with a simple lifting device, eliminating the need for additional large lifting devices during equipment maintenance. This greatly reduces the difficulty of equipment maintenance.

Products Structure

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

Technical Parameter

Multiple types are available, ensuring that there is always a suitable one for you.

| Model |

Throughput (t/h) |

Max. feeding size |

| Central feeding with circular cascade feeding |

Fully central feeding |

Soft material (mm) |

Hard material (mm) |

| CLV7615 |

150~280 |

70~140 |

35 |

30 |

| CLV8522 |

240~380 |

120~200 |

40 |

35 |

| CLV9532 |

350~540 |

180~280 |

45 |

40 |

| CLV1145 |

500~640 |

250~640 |

50 |

45 |

| CLV1150 |

550~745 |

344~368 |

55 |

45 |

| CLV1263 |

650~850 |

454~486 |

60 |

50 |

Remark: The output may vary depending on the nature or grain size of the feeding material.

Product show

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.