Wide Feeding Opening / Deep Crushing Cavity / High Impact

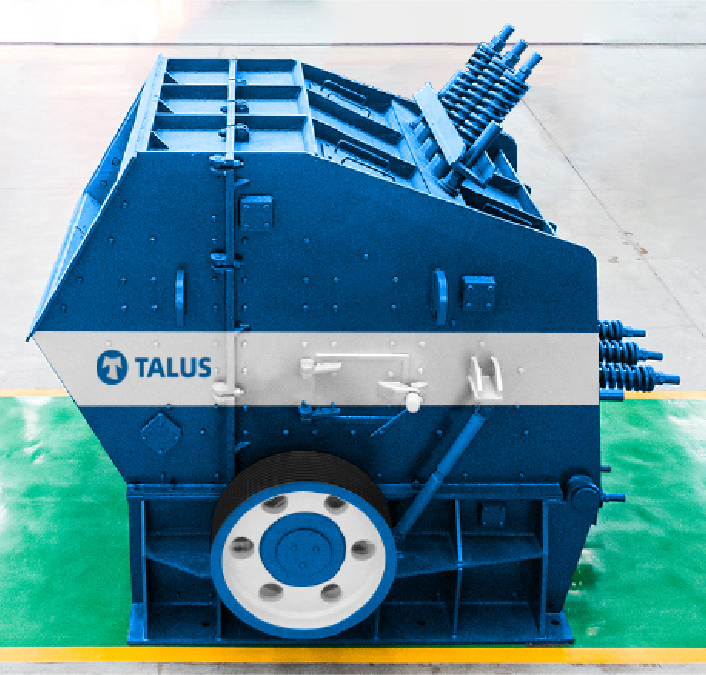

PF Impact Crusher

Capacity: 30~800 t/h

Product Introduction

The PF series impact crusher is a newly developed crushing equipment designed and manufactured by Talus Equipment Manufacturing. It incorporates valuable feedback from customers who have used the crusher and combines years of production experience. The crusher adopts a new manufacturing process and features a special structural design. The finished product has a cubic shape with excellent granularity, free of tension and cracks. It can crush various coarse, medium, and fine materials such as granite, limestone, and concrete, with a feeding particle size not exceeding 300-700mm and a compressive strength not exceeding 350MPa. Furthermore, the discharge size can be adjusted to meet diverse crushing specifications.

High Crushing Ratio

High Productivity

Security and Stability

High Comprehensive Benefit

Easy Operation and Maintenance

Good Granularity of Finished Product

Product Performance

Large Crushing Ratio and Uniform Granularity

Large Crushing Ratio and Uniform Granularity

High Productivity!

① Generous feeding opening, deep crushing cavity, and a heavy-duty rotor are adopted. Finite element force analysis is conducted to ensure a larger rotational inertia, resulting in a higher crushing ratio and improved crushing capacity.

② The clearance between the impact plate and hammer bar can be flexibly adjusted. By designing the grinding cavity, the discharge particle size can be controlled, ensuring good granularity and low content of stone powder.

Simple Body Structure - Stable and Reliable

Simple Body Structure - Stable and Reliable

Shortened payback period!

① The crusher has strong product universality. By adding a grinding rack, the double cavity crusher can be converted into a triple cavity crusher without replacing other parts, reducing the need for secondary investment.

② The design of the liner is standardized, providing strong interchangeability. This reduces the variety and inventory of spare parts, resulting in reduced customer investment.

Longer Service Life - Reduced Production Costs

Longer Service Life - Reduced Production Costs

Hydraulic lid opening and easy replacement!

① The utility parts are made of high chromium material and composite casting utility materials. They undergo rigid thermal treatment, ensuring good impact resistance and utility performance, thus prolonging the service life of the equipment and utility parts.

② The impact crusher is equipped with hydraulic flap devices on both sides of the rack, making it easy for users to open the rack and replace parts. The hammer bar locking device simplifies, facilitates, and accelerates the replacement of hammer bars.

Outstanding Machining and Assembly Technology

Outstanding Machining and Assembly Technology

Overload and tramp iron protection devices ensure smoother equipment operation!

① Before assembling the rotor, a static and dynamic balance test is conducted. The main axis is machined using excellent forging parts and is connected using an expansion sleeve tightening method, ensuring reliable equipment operation.

② Optimized overload and tramp iron protection devices are implemented. When the impact crusher exceeds its safe load, the clearance between the impact plate and discharge opening is regulated to prevent equipment shutdown caused by overload.

Operation Principle

Impact crusher is a type of crushing machine that utilizes impact energy to break materials. When the machine is in operation, driven by an electric motor, the rotor rotates at high speed. The material enters the action area of the hammer bar, where it is crushed by the rotating hammer bar on the rotor. The crushed material is then thrown to the impact device for further crushing before bouncing back to the hammer bar reaction area for secondary crushing. This process repeats itself as the material enters primary, secondary and tertiary impact cavities, progressively decreasing in size, for repeated crushing, until it reaches the required granularity and is discharged from the opening. The clearance between the impact rack and the rotor can be adjusted to change material discharge granularity and shape.

Technical Parameter

Multiple types are available, ensuring that there is always a suitable one for you.

| Model |

Max. Feeding size (mm) |

Capacity (t/h) |

Motor Power (kW) |

| PF-1820 |

800 |

550-800 |

630-710 |

| PF-1620 |

700 |

400-600 |

500 |

| PF-1520 |

700 |

350-450 |

400-450 |

| PF-1320 |

500 |

160-350 |

260-300 |

| PF-1318 |

350 |

150-260 |

220-260 |

| PF-1315 |

350 |

120-250 |

180-220 |

| PF-1214 |

300 |

90-180 |

132-160 |

| PF-1210 |

300 |

70-130 |

110-132 |

| PF-1010 |

300 |

50-90 |

55-75 |

| PF-1007 |

250 |

15-60 |

37-55 |

Products Structure

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

Large Crushing Ratio and Uniform Granularity

Large Crushing Ratio and Uniform Granularity

Simple Body Structure - Stable and Reliable

Simple Body Structure - Stable and Reliable

Longer Service Life - Reduced Production Costs

Longer Service Life - Reduced Production Costs

Outstanding Machining and Assembly Technology

Outstanding Machining and Assembly Technology