Combined sand washing, dewatering and fine sand recycling function

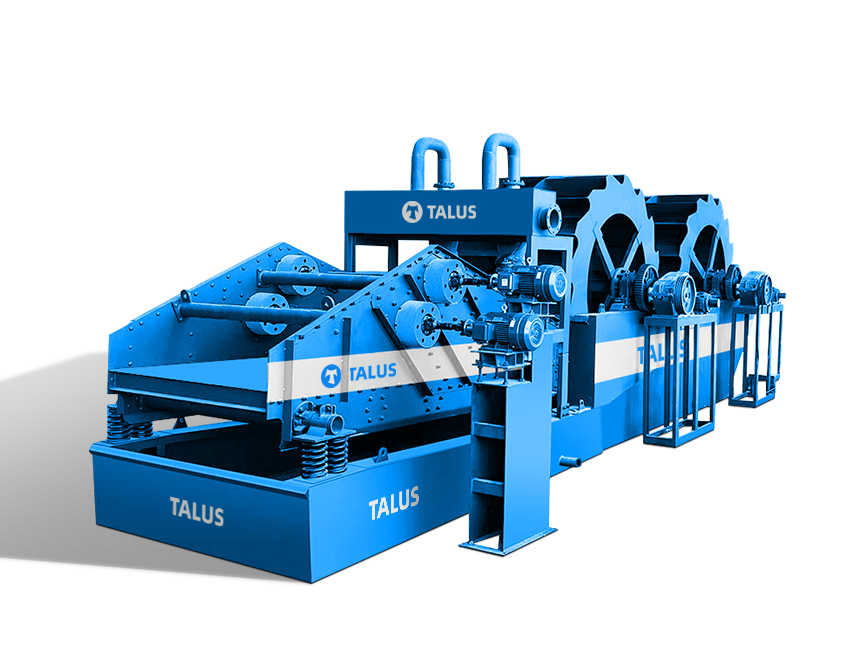

Sand Washing and Fine Sand Recycling Integrated Machine

Capacity: 40~220t/h

High sand washing efficiency

Long service life

Security and stability

Low power consumption

High level of automation

Large processing capacity

Product Introduction

Sand washing and sand recycling integrated machine combines functions of sand cleaning and fine sand recycling, extracting fine sand from mud water discarded after sand washing to obtain 0-5mm sand with a reasonable gradation of coarse and fine sand. Our sand washing wheel features a simple structure and is highly convenient to operate and maintain. The equipment is divided into two parts, the wheel sand washer and the fine sand recycling device. Customized options include Double rows of wheel or three rows of wheel, depending on customer requirements. The fine sand recycling device is configured based on the amount of water to be treated and concentration of the sand water mixture. This ensures the appropriate selection and quantity of separators, slurry pumps, and dewatering screens.

Applicable materials

Mechanic sand

River pebbles

Granite

Natural sand

Limestone

River sand

Quartz sand

Basalt

Operation Principle

When bucket sand washer works, motor drives the impeller to rotate slowly through triangle belt, reducer and gear wheel after deceleration. Sand and gravel enter the washing tank from feeding trough, where they roll and grind each other under the impeller’s driving force, removing impurities covered on sand and gravel surface. Meanwhile the water vapor layer covering the sand particle is destroyed to facilitate dehydration. Simultaneously, water is added to create a strong water flow, which can promptly remove impurities and small foreign objects with low specific gravity. These impurities are discharged from the outlet of the washing tank, completing the cleaning function. The clean sand and gravel are taken away by the blades and poured into the discharge trough from the rotating impeller, completing the sand cleaning process. The sand processed in sand washer is clean and uniform in particle size. It is easy to operate and maintain and has good safety performance.

Technical Parameter

Remark: The output may vary depending on the nature or grain size of the feeding material.

| Model |

Impeller diameter (mm) |

Impeller width (mm) |

Water consumption (m³/h) |

Capacity (t/h) |

| XS2600-35-1224 |

2600 |

1200 |

≤80 |

40-60 |

| xS3016-50-1530 |

3000 |

1600 |

≤120 |

60-95 |

| 2xS3016-70-1530 |

3000 |

1600 |

≤120 |

60-95 |

| xS3024-70-2040(D) |

3000 |

2400 |

≤200 |

80-120 |

| 2xS3024-120-2442(D) |

3000 |

2400 |

≤250 |

120-160 |

| xS3624-120-2442(D) |

3600 |

2400 |

≤250 |

150-220 |

| 2xS3624-120-2442(D) |

3600 |

2400 |

≤280 |

150-220 |

Products Show

From exterior design to internal structure, every detail has been meticulously considered and thoroughly tested.

Well-mixed gradation of coarse and fine sand.

Well-mixed gradation of coarse and fine sand.

High work efficiency and increased output of finished sand.

High work efficiency and increased output of finished sand.

Low energy consumption, small footprint and green environmental protection.

Low energy consumption, small footprint and green environmental protection.

Integrated design for extended service life.

Integrated design for extended service life.

Easy repair and low maintenance cost.

Easy repair and low maintenance cost.

Customized options available for different products models.

Customized options available for different products models.

Produces cleaner finished products compared to traditional sand washers.

Produces cleaner finished products compared to traditional sand washers.