High efficiency / High quality / High environmental protection / Intensification

Semi-underground Stepped Sand Making Plant

Processing Capacity: 60-220t/h

Scope of application: It is suitable for processing and shaping various rocks, river pebbles, construction garbage, and other materials. It produces broken stones and high-quality mechanism sand that meet certain proportions and quality requirements.

Product Introduction

The STSL series semi-underground stepped sand making plant is a relatively simple sand making plant that does not require encapsulation and has a lower investment cost compared to a tower-like sand making plant. It adopts a tower-like structure, but the layout is more scattered. It installs the feeding conveyor system and crushing sand making system underground and encloses the ground devices with a structure to reduce noise and dust pollution. It is commonly used for the renovation and upgrading of old production line projects.

Technical Feature

Higher practicality and lower overall investment costs

Higher practicality and lower overall investment costs

The semi-underground stepped sand making plant has lower overall investment costs and higher practicality compared to a tower-like sand making plant. It features a flexible layout, making it ideal for projects with limited factory or site areas.

Modular design makes installation easier

Modular design makes installation easier

All modules are pre-fabricated and assembled according to the real proportion of the customer's site, allowing for trial production in factory. Its modular design shortens on-site installation time and allows for easy dismantling and reinstallation, ensuring quick relocation and reassembly according to construction requirements.

High-quality finished sand products with a more reasonable gradation

High-quality finished sand products with a more reasonable gradation

Sand making tower system adopts Talus dual power sand maker independently developed by Henan Talus Equipment Manufacturing, which has stronger crushing and stone reshaping abilities, and the finished sand produced has full grains, round surface and uniform particle distribution. The gradation, particle shape and powder content of sand are more reasonable. The proportion of 0.15-0.6mm fine sand is significantly increased, while the proportion of 2.36-4.75mm coarse sand is reduced, and the powder content is between 3-15%, which can be adjusted in a wide range.

The system is more intelligent and highly automated

The system is more intelligent and highly automated

Through a centralized control system or PLC automatic control system, it can realize online real-time monitoring of equipment production status, adjusting operation of the whole set of equipment, one-key start-stop, abnormal alarm, emergency shut down, automatic stabilization of the operation parameters, etc., which ensures the quality of finished sand and production line capacity to be smooth and stable, as well as the safety, stability, and continuity of all the production links.

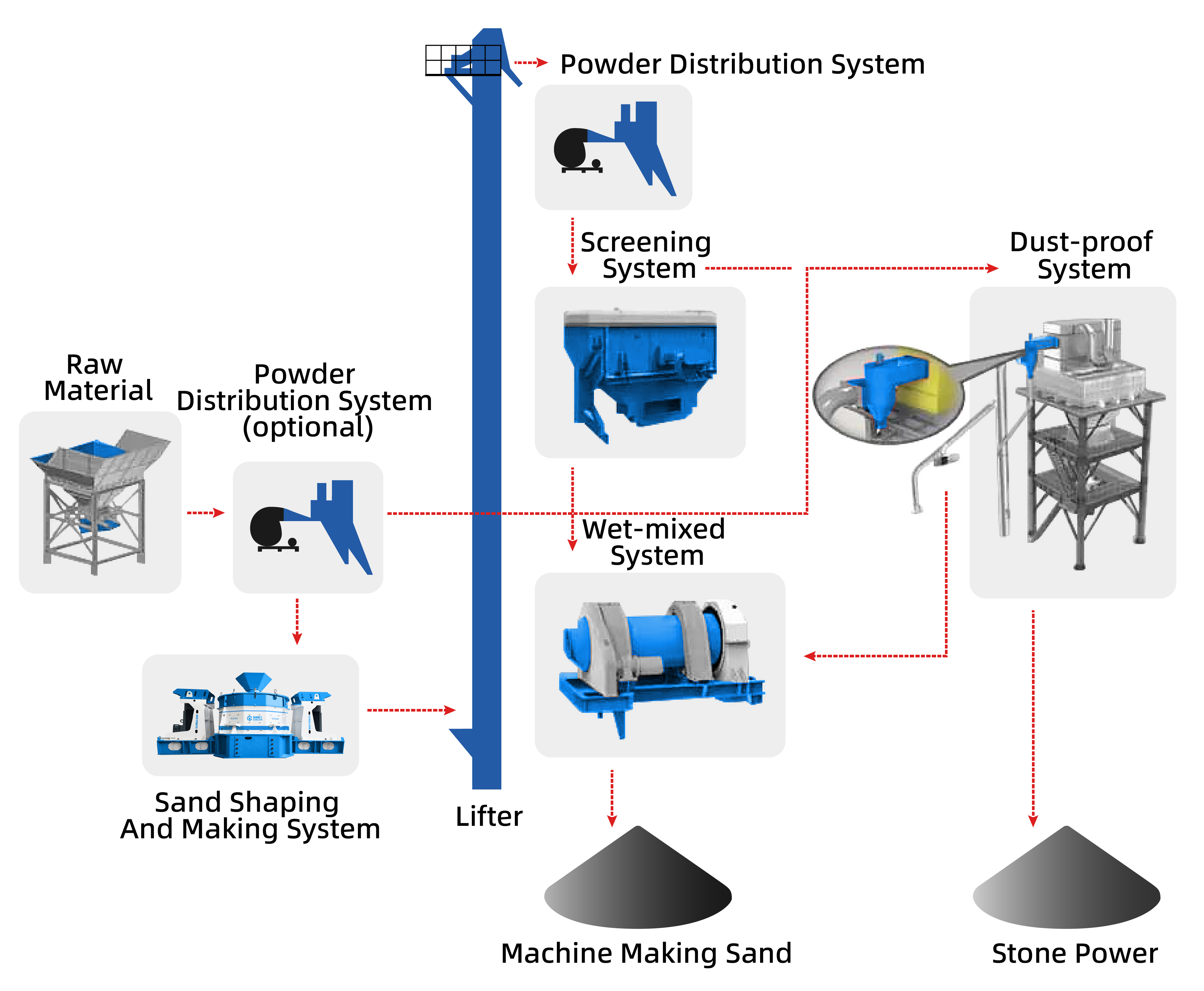

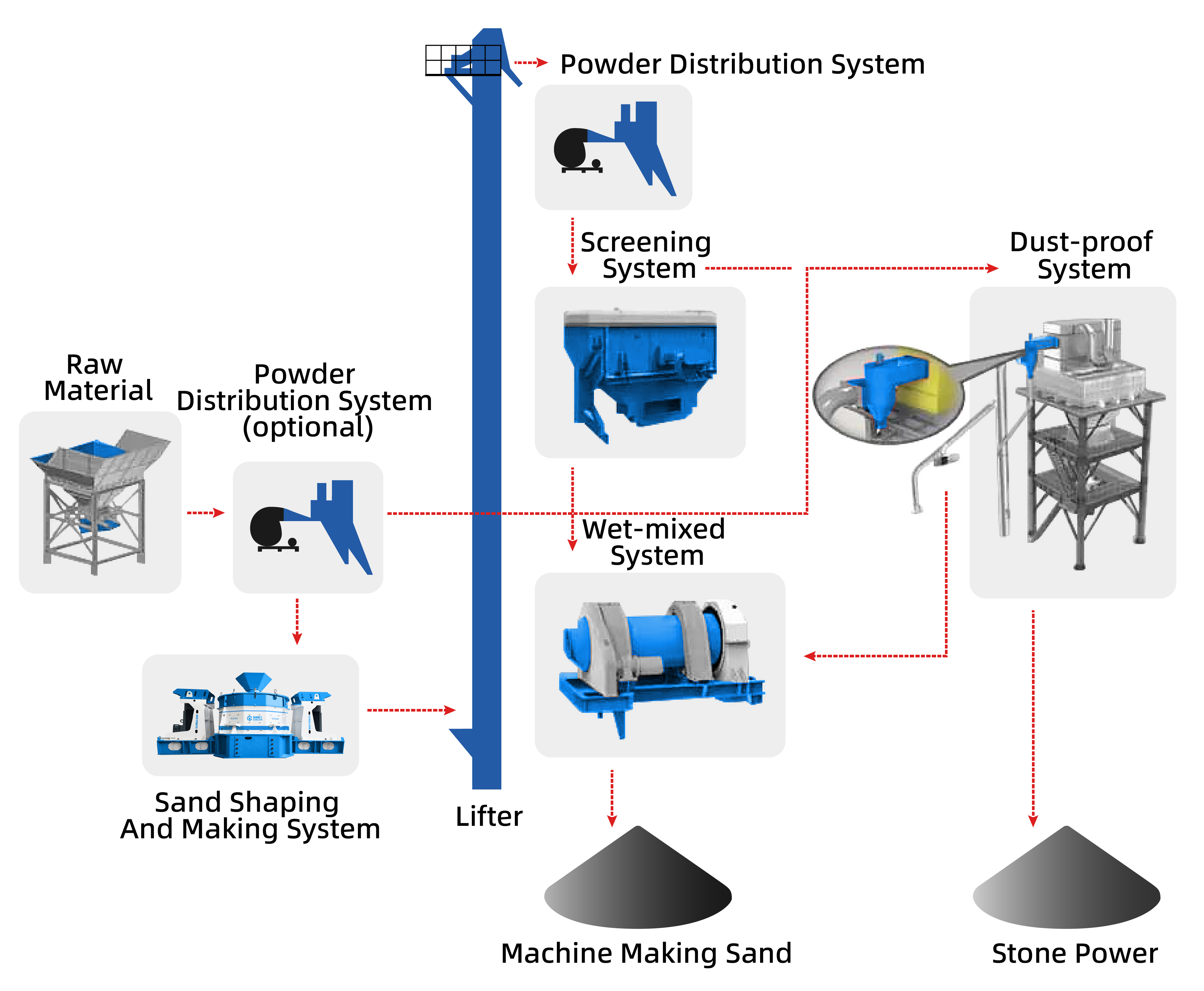

Process flow and operation principle of sand making plant

The STSL stepped sand making plant is a tower-like sand making system that adopts a dry production process. It consists of a loading material conveying system, sand reshaping and screening system, dust-proof system, stone powder storage system, and electrical control system. The raw materials are fed into the top floor through a bucket elevator. Broken stones ranging from 0-60mm are then sent to the Talus sand maker through a raw material conveyor belt. Through high-frequency rock-on-rock grinding, the material is delivered to the stone powder separation cavity. The sand powder content is regulated by adjusting the size of the air inlet of the powder control box and the air volume of the system. The processed material enters the sorting screen to select fine crushed stones, stone powder, and semi-finished sand. The stone powder is collected as fine stone powder after being processed by a dust-proof and dust collection system, while the semi-finished sand is evenly mixed by a humidifying mixer to form fine mechanism sand.

Technical Parameter

Remark: The output may vary depending on the nature or grain size of the feeding material.

| Model |

STSL220 |

STSL160 |

STSL60 |

| Sand maker type |

TLS1553 |

CLV1263 |

CLV1145 |

| Vibrating screen |

2YK3070 |

2YK2460 |

2YK2160 |

| Max. feeding size |

≤60mm |

≤60mm |

≤60mm |

| Processing capacity |

220t/h |

160t/h |

60t/h |

| Stone powder content |

3~15% controllable |

| Control system |

PLC control or centralized control

|

Stepped Style Sand Making Plant - 3D Rendering

Experience our product through a multi-angle display. To see it in person, please make an appointment for a physical factory visit.

Higher practicality and lower overall investment costs

Higher practicality and lower overall investment costs

Modular design makes installation easier

Modular design makes installation easier

High-quality finished sand products with a more reasonable gradation

High-quality finished sand products with a more reasonable gradation

The system is more intelligent and highly automated

The system is more intelligent and highly automated